Business

TOP

TOP

TOP

TOP

Business

The aluminum alloys produced by our company represent a key sector in the recycling industry.

Used aluminum (scrap) is collected and remelted to manufacture ingot products for die-casting or foundry alloys.

The produced alloy ingots are primarily supplied as materials for automotive components, and are also provided to the electronics and steel industries, among others.

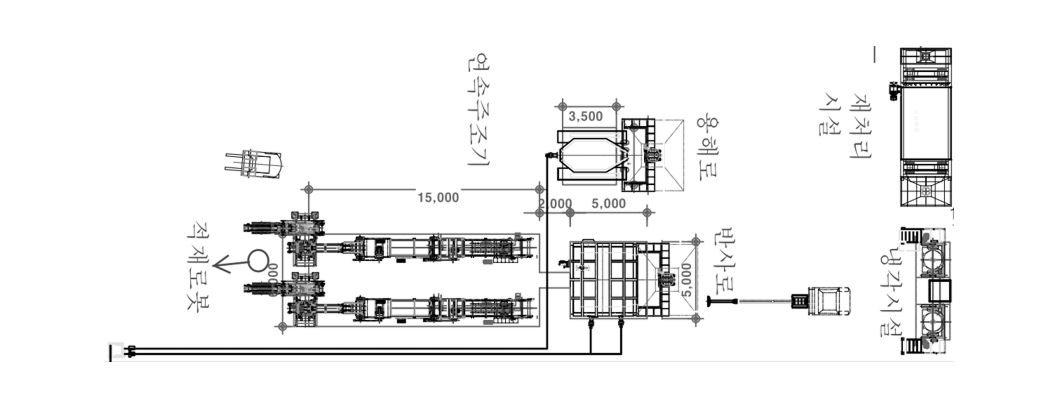

We have the following equipment: one reflective furnace, one rotary melting furnace, and two casting machines.

| 1 Reflection Furnace | Production Capacity: 25 MT/Cycle |

| 1 Rotary Melting Furnace | Production Capacity: 3 MT/Cycle |

| 2 Continuous Casting Machines | Used for manufacturing products and ingot supports |

Through a 25-ton reflection furnace, it is possible to produce 500 tons of aluminum ingots and 200 tons of SOW (Secondary Aluminum Alloy).

Approximate daily production: 30 tons of aluminum ingots (based on a 5-day workweek).

1 | 25-ton Reflection Furnace |

2 | 3-ton Rotary Furnace |

3 | Robotic Charging System |

4 | Continuous Casting Machine |

5 | Reprocessing Facility |

6 | Cooling Facility |

Raw Material Receipt

Carefully selected high-purity raw materials, such as aluminum alloys and silicon metal, are safely received and rigorously managed.

Heat Treatment & Melting

Using specialized equipment, raw materials are melted at high temperatures, preparing for casting with uniform quality.

Impurity Removal

Oxides and other impurities are removed from the melted metal, ensuring purity and product quality.

Mold Casting

Molten metal is poured into pre-designed molds to shape it into the desired form.

Solidification

A heat treatment process that creates a uniform internal structure, enhancing mechanical strength and durability.

Loading

The molded products are properly loaded along the automated line and prepared for subsequent processes..

Inspection

Using precision equipment, the products are thoroughly inspected for specifications, strength, and defects.

Shipment

Products that pass inspection are safely packaged and shipped to clients, with delivery schedules and logistics carefully managed.

We supply products according to agreements, bids, or private contracts with our partners, ensuring delivery according to their schedules.

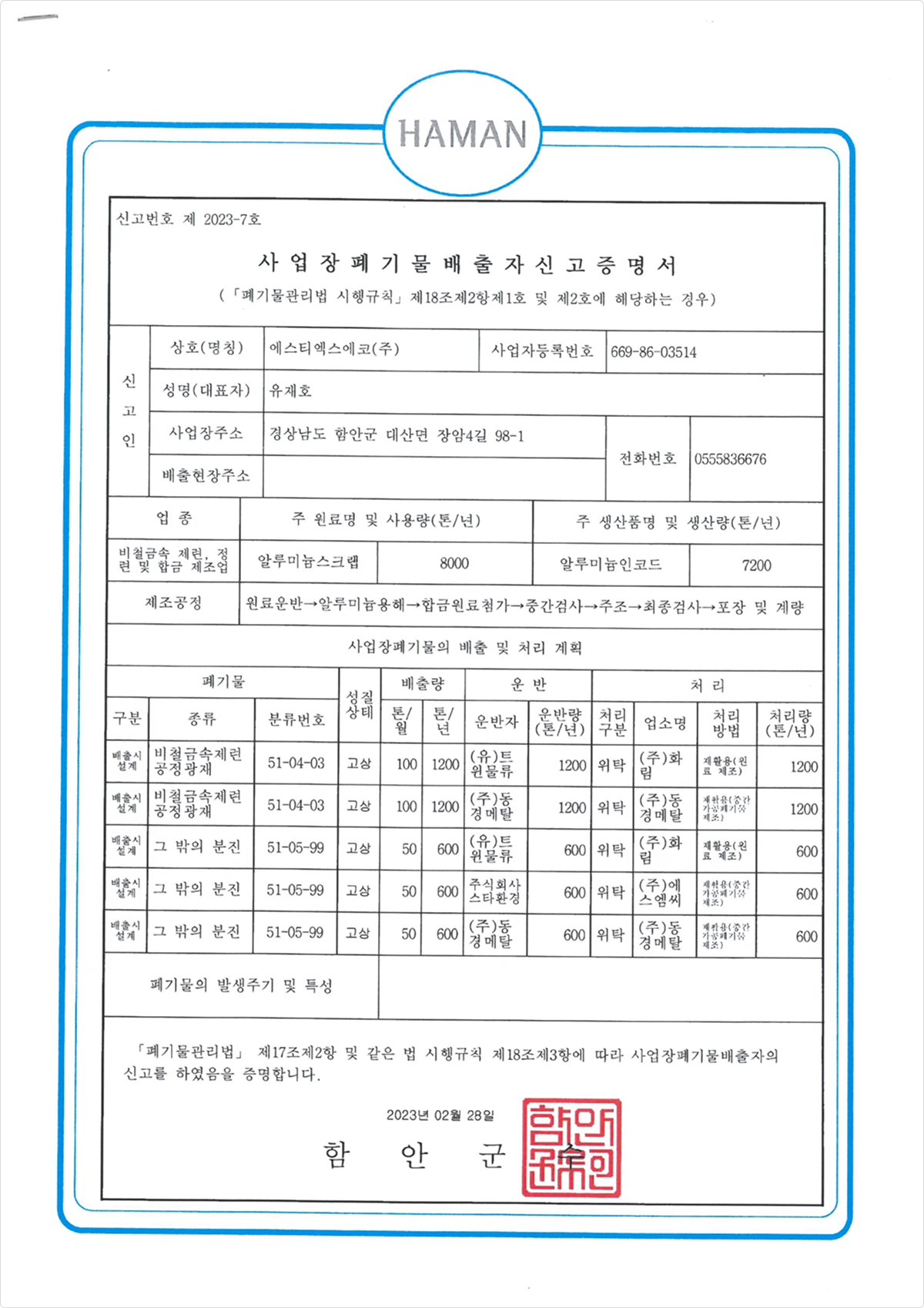

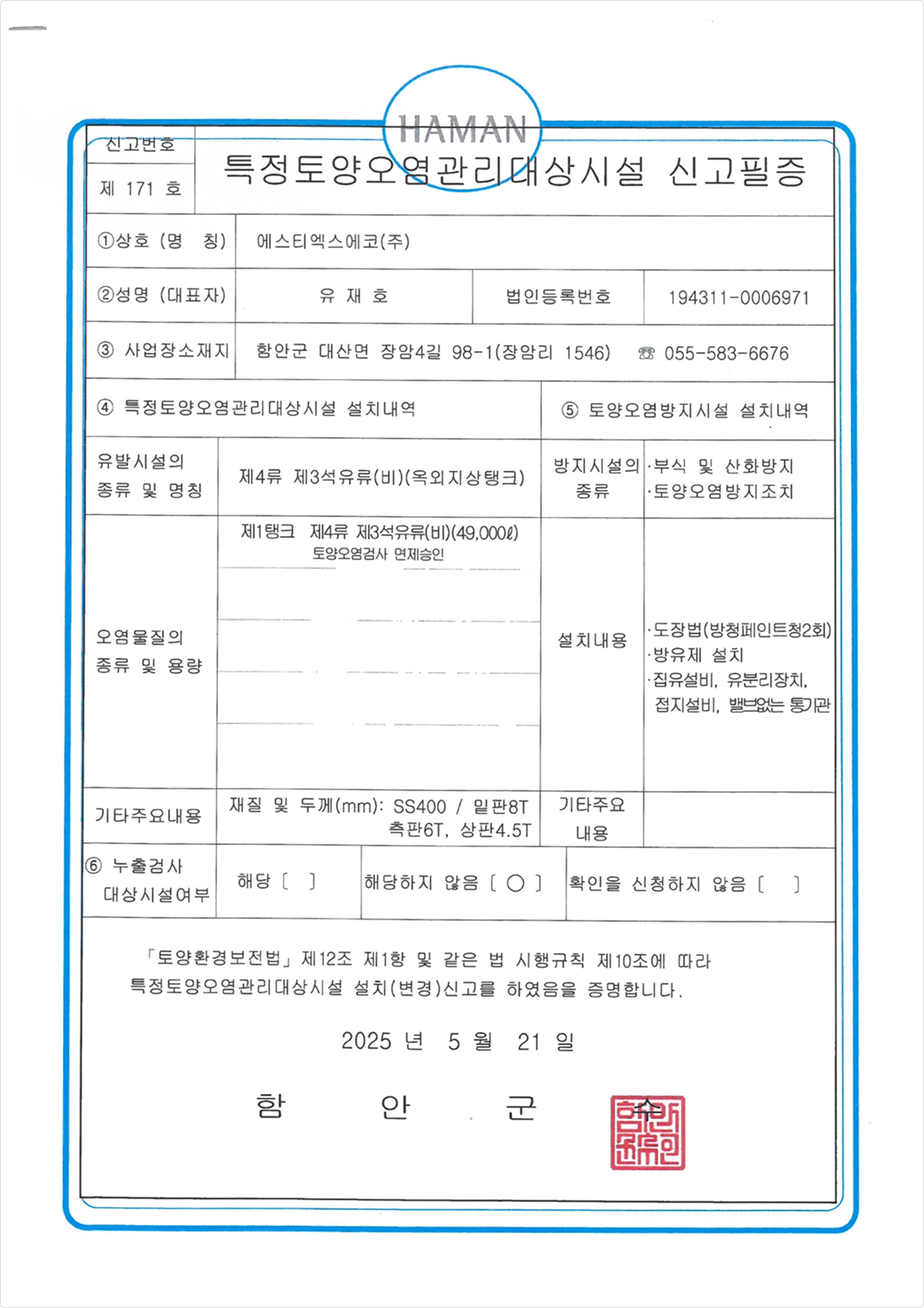

We have officially validated the reliability of our products and processes through various industry certifications and permits. We continue to maintain transparent operations and quality-focused management.

* Click on the image to view a detailed, enlarged version.

Close